01. Indexed kinematics with Eri machine

What is indexed kinematics?

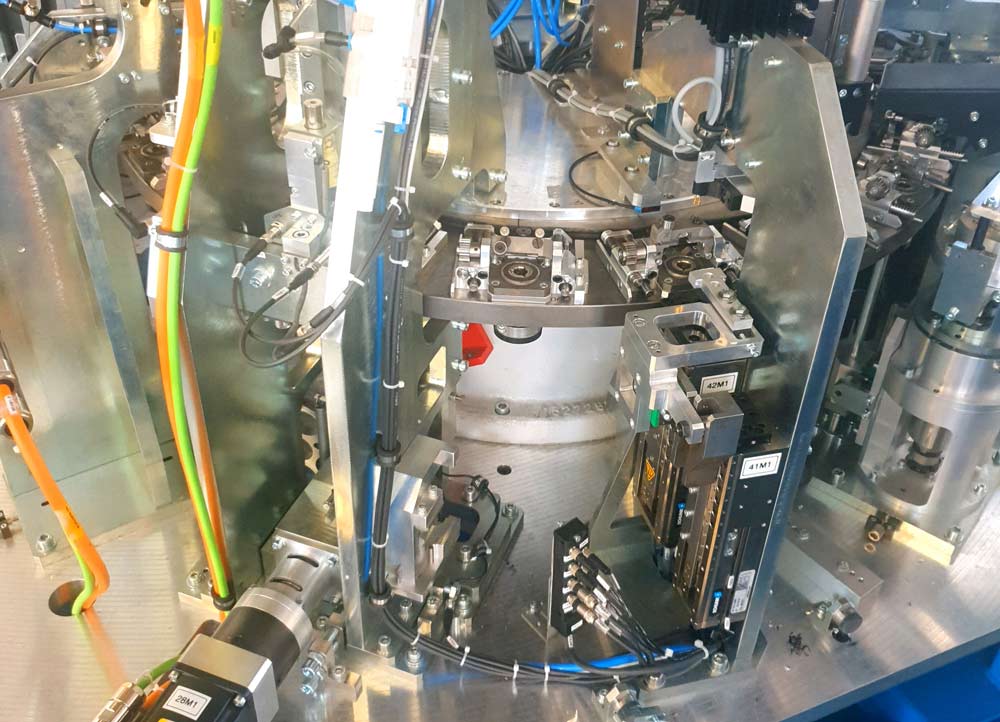

A special machine with indexed kinematics allows the displacement from station to station of an assembly "product holder" which allows to carry out the various operations to be carried out on the product (assembly, control, marking, ...).

The machine cycle is divided into a transfer phase from station to station and a work phase at the station. However, part of the process phase can be carried out in "hidden" time, during the transfer phase, to optimize the cycle time.

ERI implements the most suitable transfer systems for the specific applications requested by its customers.

These transfer systems can be:

- Machines with trays driven by :

- A mechanical indexer or indexing table: step-by-step transfer by a cam driven by an asynchronous motor or a servomotor.

- A servomotor.

- A torque motor.

- Magnetic transfer

- Linear transfers:

- Transfer consisting of a machined link chain driven by an indexer or a torque motor.

- Magnetic transfer.

02. Torque motor

How does a torque motor work and what is its interest?

Torque motors are a special category of brushless permanent magnet servomotors. Since the load is mounted directly on the rotor without intermediate transmission elements, torque motors are classified as a direct drive solution.

The torque motor driven rotary table ensures constant torque, rigid load coupling (no backlash due to transmission) and maximum dynamics, especially at high loads. These rotary tables are highly efficient and extremely quiet thanks to their high efficiency and the absence of gearboxes.

ERI integrates torque-driven rotary tables for applications that require short cycle times and high accuracies.