01. Continuous kinematics with ERI machine

What is continuous kinematics?

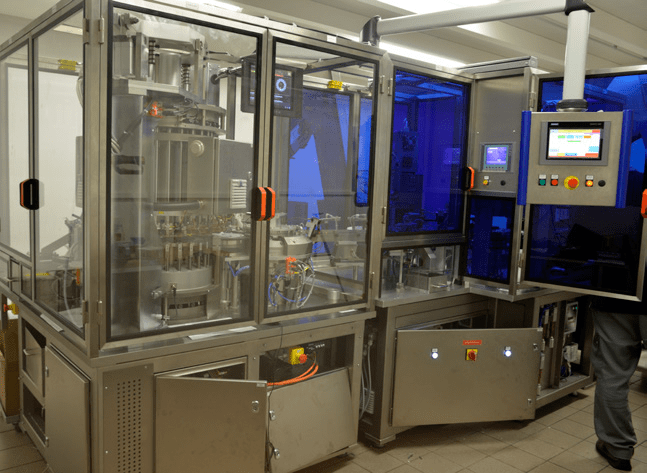

ERI has a historical know-how in the implementation of continuous motion production machines.

It meets the requirements of high production rates for the manufacture, control and assembly of products in large series (4,000 to 50,000 parts per hour).

This technology of synchronization of movements is possible thanks to the great mastery of mechanics, electronic and mechanical cam drive and process control techniques

For all your special kinematic assembly machines, don't hesitate to call on an expert who will be able to accompany you and give you sound advice to optimize your industrialization.

02. Its function

How does continuous kinematics work?

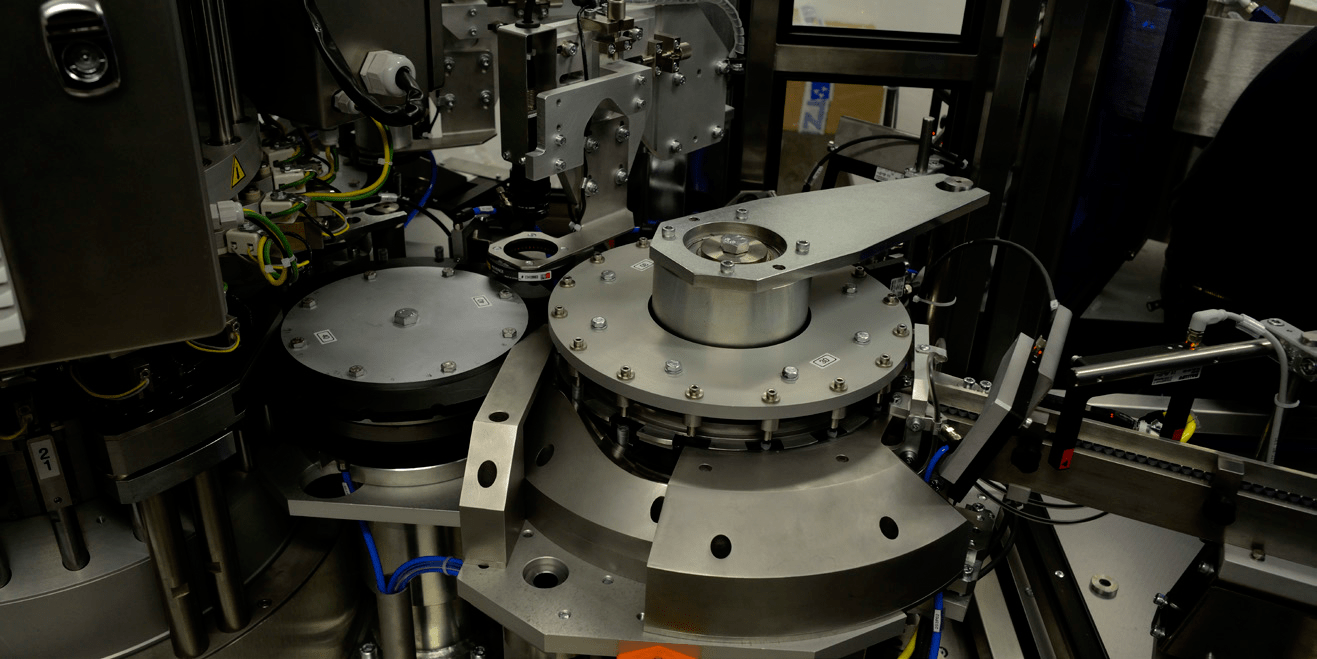

The special feature of continuous kinematics is the ratio of process time to cycle time. The tools and components are transported by continuously rotating barrels at a constant speed. Thanks to the continuous kinematics, the time spent on transporting the part is hidden. The number of tools is defined by the technological time. This performance makes it possible to produce high-speed machines.

For example, a barrel with 24 spindles (1 part and 1 tool per spindle) rotating at a speed of 18.75 revolutions per minute can perform functions with a technological time of more than 2 seconds and provide an output of 450 parts per minute. Thus, operations such as welding, pistoning, hot forming or delicate assembly steps can be carried out at high speed with the utmost care. The special machines we manufacture always respect your technical needs and meet all your requirements. Continuous kinematics is a preferred solution for many industries. You too can switch to continuous kinematics with ERI!

03. The diversity of technologies at the service of customization

Continuous kinematics adapted to your special machine

It is thanks to this competitive spirit that ERI pushes the limits of special machines. No matter the shape or characteristics of your product, we will find THE solution.

We master techniques such as mechanical follower distribution , which allows us to feed a continuous kinematics with products with particular shapes. ERI also offers barrels mounted on vertical, horizontal or inclined axis in order to adapt to your environment or work surface.

At the time of the study, our engineers evaluate your criteria and adapt the realization of your machine by taking advantage of the know-how of each technology. Whether it is continuous kinematics, indexed kinematics or a combination of both, the ERI engineering team will propose the most suitable solution, taking into account each of your needs.

ERI takes care of your products by offering them a "safe entry". This technology, aimed at slowing down the speed of a barrel during product entry, allows the integrity of the parts to be respected without loss of speed.

ERI offers you customized solutions!

04. The numbers

Continuous kinematics in a few numbers

ERI has been working with technologies that integrate continuous kinematics for special machines for many years. Our know-how has been passed on to our teams to provide you with a high quality service over time. The technological developments linked to continuous kinematics have shaped the major innovations of ERI:

- Since 2007, roller assembly machine with an output of 48,000 parts per hour.

- Since 2013, Machine for marking and assembling syringes with a rate of 8000 parts per hour. It is a mix between a machine in indexed kinematics to realize pad printing and continuous kinematics to realize pistoning.

- Since 2015, Needle guard assembly machine with an output of 25,000 parts per hour.